The impact of OAP extends to a wide variety of industries and applications. From heavy industrial machinery to precision-dependent aerospace systems, OAP’s ability to protect critical components from rotational irregularities makes them a versatile and indispensable asset. Applications extend beyond traditional automotive engineering to encompass a wide range of industries where precision and reliability are critical.

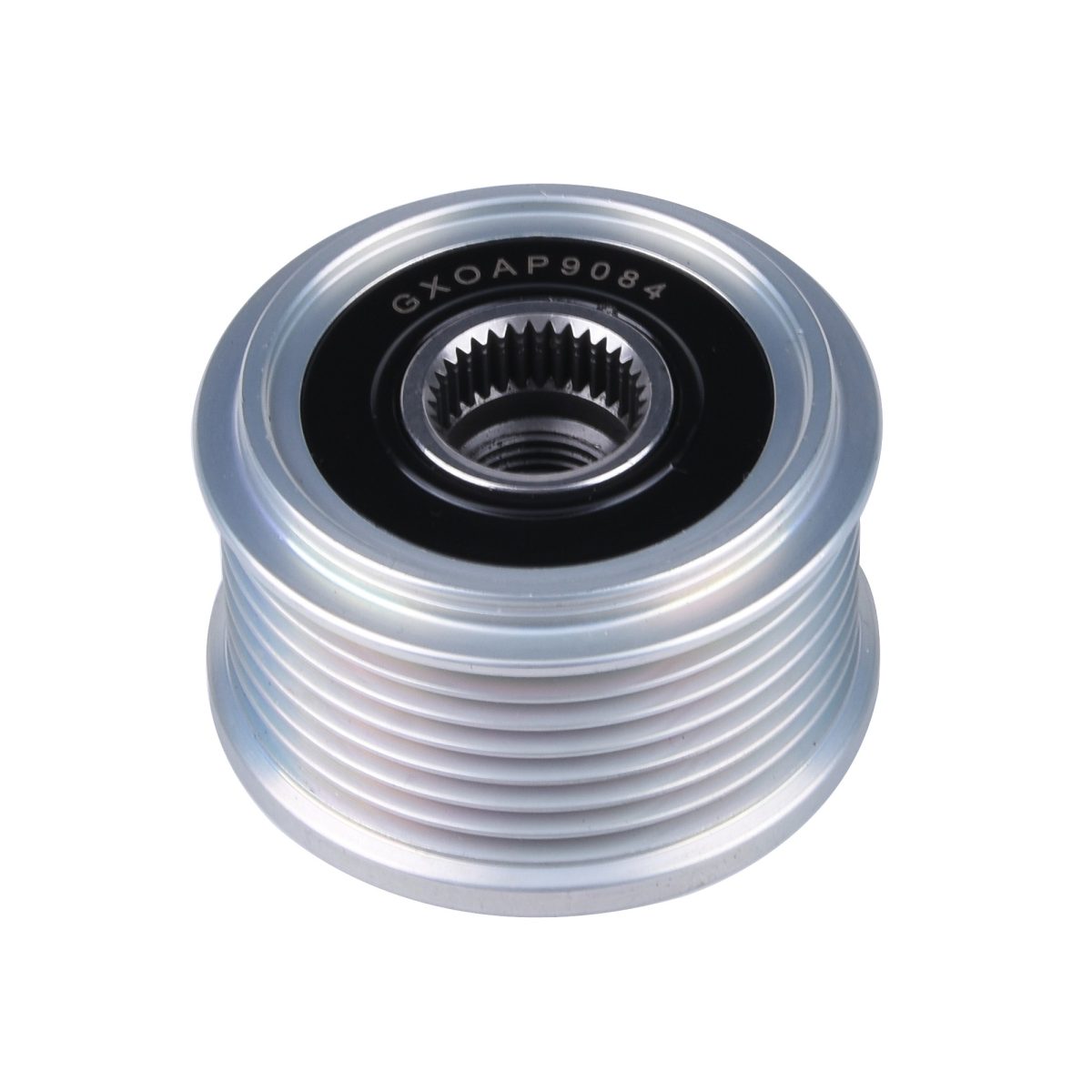

The decoupled overrun alternator pulley, or overrun alternator pulley (OAP), is a key component in a vehicle’s powertrain that ensures smooth, efficient operation by reducing rotational irregularities. The OAP consists of two components (outer and inner rings) that are cleverly designed to seamlessly adapt to varying operating speeds, protect the alternator and improve overall system performance.

OAP” is the abbreviation of overrunning alternator pulley

OAP pulley is also called one-way alternator clutch pulley..

Commonly said the alternator with clutch, in fact, is the one-way alternator pulley.

The function of the OAP is to insulate the alternator from rotational irregularities. Its function is to decouple the alternator from the belt drive, where the alternator has the highest rotational moment of inertia. The use of the OAP ensures that only the accelerated portion of the crankshaft force transmitted to the belt drive is used to drive the alternator.

Characteristics difference between OAP pulley and normal alternator pulley:

1. One-way slipping performance, the basic principle is similar to the one-way clutch gear on the starter.

2. It can be divided into two parts: outer ring and inner ring, if the speed of inner ring (i.e. rotor speed) exceeds the speed of outer ring during operation, the belt will slip immediately, and then the inner ring will disengage from the outer ring.

3. It has a plastic cover, which is used for driving the alternator. (It can be divided into two parts: the outer ring and the inner ring. If the speed of the inner ring (i.e. rotor speed) exceeds the speed of the outer ring during operation, the pulley will slip immediately, and then the inner ring and the outer ring will be detached from each other.)3. There is a plastic cover over the port to prevent dust from entering the interior, commonly known as the dust cover.

4. It rotates directly on the rotor shaft by means of a thread on its back. Therefore, there is no hexagonal nut on the outer face of the wheel.

5. The one-way alternator pulley is wedge shaped to give the generator good performance in operation.

The OAP is designed to insulate the alternator from rotational irregularities, thereby protecting it from fluctuations caused by operating irregularities. The OAP’s complex design allows it to effectively manage the speed differential between the inner (rotor speed) and outer rings during operation. This dynamic feature ensures that the OAP is able to respond quickly to speed differentials, thus preventing excessive stress on the alternator and associated drive belt. By effectively managing rotational irregularities and speed differences, the OAP helps to improve the overall efficiency and reliability of the powertrain system. This critical role not only ensures smooth alternator operation, but also minimizes the impact of torque fluctuations on the drive belt, improving fuel efficiency and reducing emissions.